About TWIGA

Twiga is the leading manufacturer of glass wool insulation in India having a twenty-five year track record of supplying domestic and export customers with world-class products for thermal and acoustic insulation. An ISO 9001:2008 certified company, Twiga commenced its operations in 1979 and is a technology licensee of Isover Saint Gobain, the leading manufacturer of insulations worldwide.

S.L.J. Holdings is the authorized dealer for TROX Products and solutions in Sri Lanka, Australia & Malaysia.

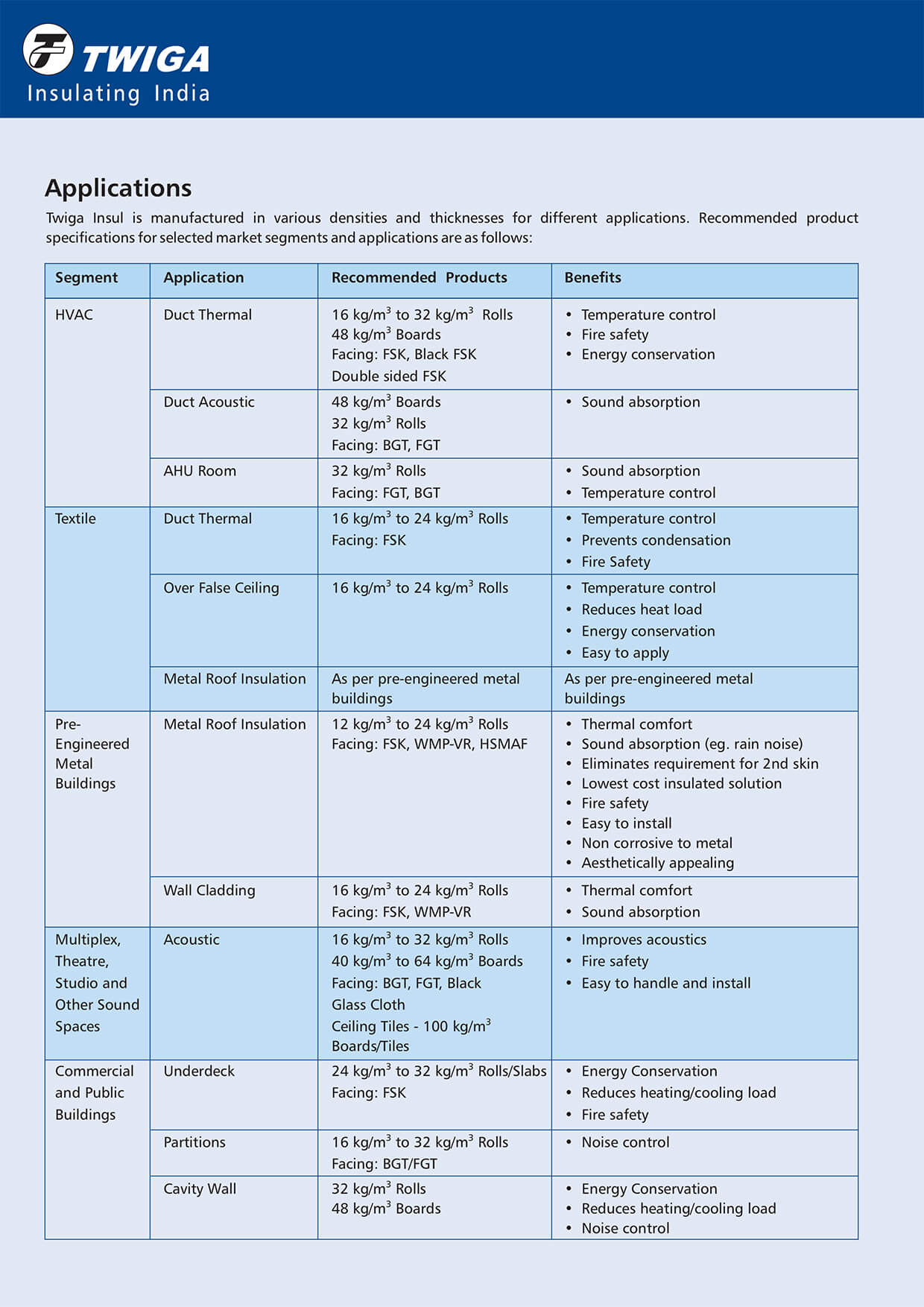

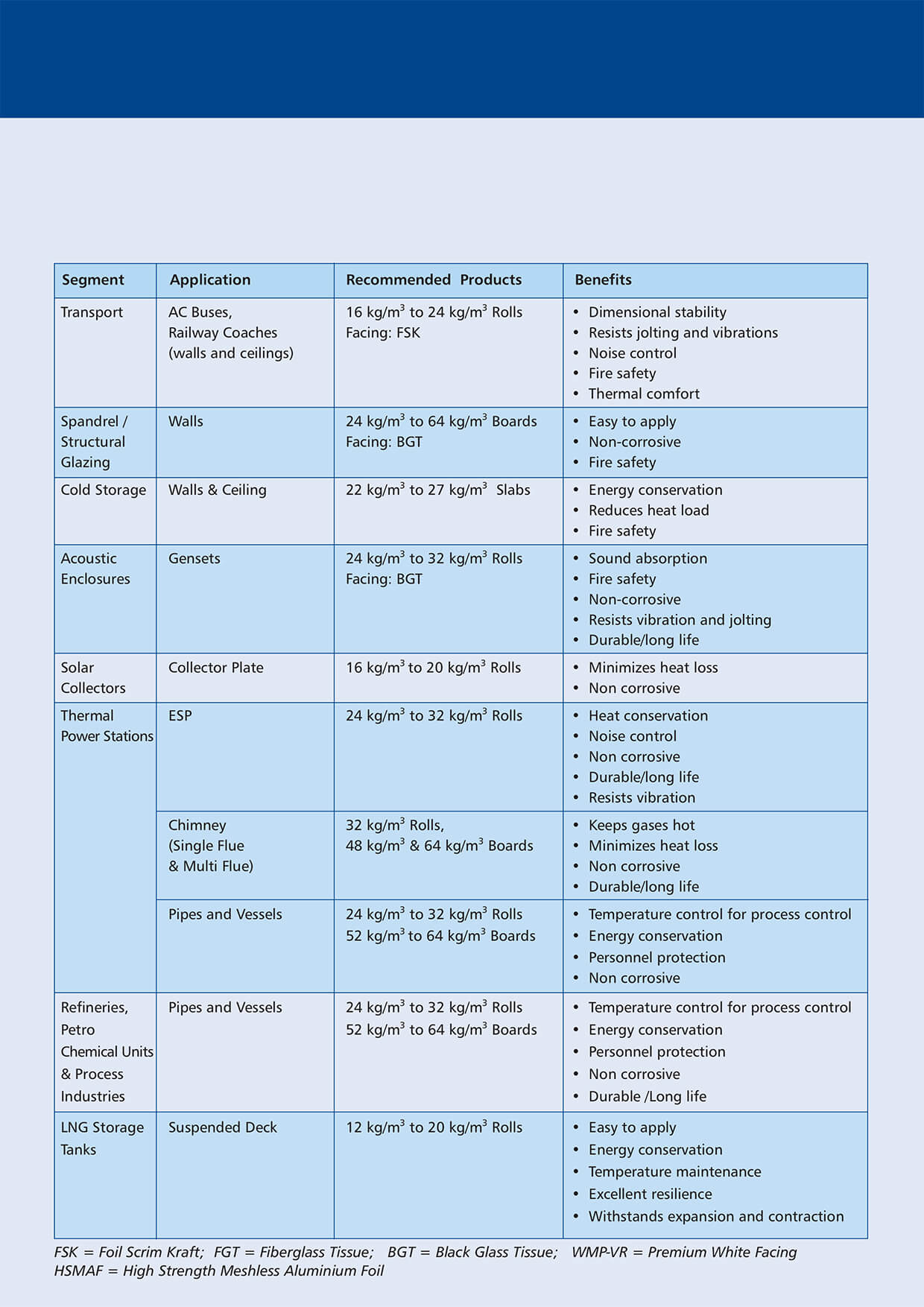

TWIGA - Products Range

Twiga Glasswool Insulation

Twiga Insul is a lightweight, compressible insulation material, consisting of fine, long, inorganic glass fibers bonded together by a high temperature binder. The product is light gold in colour and its superior tensile strength, handleability and resilience offer significant advantages during transport and installation. These unique characteristics of glass wool, combined with its fire safe properties, make it especially suitable for a wide variety of thermal and acoustic insulation applications, ranging from duct and metal roof insulation to applications in solar collectors and generator acoustic enclosures.

Twiga Insul is available in rolls, slabs and boards – in various densities and thicknesses and with a wide range of factory applied facings. The product is recommended for use in both hot and cold applications ranging in temperature from minus 195° to plus 450℃.Factory applied facings include reinforced aluminium foil, fiberglass tissue, black glass tissue and a wide range of imported premium facings, which are widely used in metal building applications. Our technical sales staff will be pleased to recommend the appropriate density, thickness and facing combination for your specific application.

Twiga Insul Duct Wrap

TWIGA Insul Duct Wrap Ductwrap, a light weight thermal insulation blanket having long product life is specifically designed to wrap around air conditioning ducts. Manufactured from fine, stable and uniformly textured non combustible inorganic glass fibers bonded together by a non water soluble and fire retardant binder.

Features & Benefits :

Twiga Insul Preformed Pipesections and Lamella Mat

Twiga Insul Preformed Pipe Sections, designed for easy and rapid “snap-on” installation are a one piece moulded insulation made from shot free non combustible glass fibers bonded together with a high temperature resistant binder for pipe diameter from 20mm NB to 300mm NB. The section is available with / without factory laminated aluminium foil facings.

Twiga Lamella Mats are made from glassfiber wedges laminated with aluminum foil. Lamella Mats are compression resistant (maintains thickness at bends), easy to handle and are suitable for large pipes of diameter from 300mm NB and above.

Twiga Insul Pipe Sections and Lamella Mat is suitable for the thermal and actoustic insulation of:

- Heating and hot water service pipes

- Steam pipes up to 230ºC with bare pipe section.

- BS 476 part 7- Class 1 – SURFACE SPREAD OF FLAME NIL

- Chilled water and cold water service pipes

Features & Benefits:

- -Green Building Material : Low embodied energy, Zero ozone depleting potential, Minimum VOC

-Fire Safe : Non combustible, Does not emit toxic fumes

-Excellent thermal resistance at low cost(low thermal conductivity)

-Low cost : Easy and fast to install & Non hygroscopic

-Non corrosive to metal : No shot content / impurities

-Resistant to chemicals, oil, fungus, bacteria, rot and vermin attack

Twiga Flexible Ducts

Twiga Flexible Duct designed for HVAC systems is light weight, strong, fully flexible and compressible yet dimensionally stable.

Twiga Flexible Duct is made of double lamination of films permanently bonded to a coated spring tough steel wire helix. Thermal efficiency is provided by wrapping the exterior with a blanket of fiberglass wool insulation in various densities & thicknesses for required thermal resistance. The outer jacket is made of double laminated film with fiberglass yarn reinforcement, which acts as a vapour barrier surface as well.

Twiga Flexible Duct can widely be used in all Air Conditioning/ Ventilating Systems including commercial & office buildings, hotels, hospitals and many other industrial and residential applications.

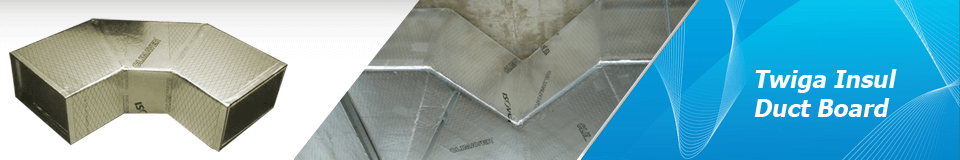

Glass Duct Board for HVAC Application

Fiberglass duct board is a rigid board of insulation material manufactured from resin bonded inorganic glass fibers. The exterior surface of the board is a factory-applied reinforced aluminium foil-air barrier and water vapour retarder. The edges of the board are formed by machine to create a ship lapped edge or grooves, to allow the grooves to be joined to build straight ducts of any size or length. Duct system components such as tees, offsets, elbows and transitions may be fabricated from flat duct board. Fibrous glass duct boards are fabricated into ducts to make a fibrous glass duct system.

Twiga Fiberglass Surface Tissue

Twiga Surface Tissue as the name suggests is a very thin tissue of fiberglass made of randomly oriented glass fibers distributed in a polystyrene binder.

Surface Tissue having excellent chemical and weather resistance is very smooth and porous and lies underneath the gelcoat.

Twiga Surface Tissue is ideal for improved surface finishes and imparts added strength to moulded FRP products Once fully hardened and sealed with resin or a gelcoat, fiberglass is waterproof, relatively light weight and when done properly it is extremely strong. It is reasonably inexpensive when compared to the alternatives.

Twiga Surface Tissue is available for both Pipe and Tank Winding (with Insoluble binder) and Hand Lay Up application (with soluble binder).

Features & Benefits:

- Imparts a reinforced resin – rich surface for general FRP products

- Suitable for hand lay-up or press moulding where intricate contours are present and also for pipe and tank winding application

- Multicompatibility binder results in softer and more flexible tissue and improved surface – laminate bonding

- Resin – rich surface prevents crack formation and improves visual appearance of final product

Twiga Fiberglass Pipe Wrap

Twiga Fiberglass Pipe Wrap is a thin flexible, uniform felt, composed of glass fibres in an open porous structure, bonded with phenolic binder that is compatible with hot coal-tar enamel. The mat may be of the reinforced or non-reinforced type.

For water, crude oil and gas pipelines, the anti-corrosive protections mostly utilized are hydrocarbon base systems (oil or pit carbon derivates) mixed with mineral fillers and reinforced with Twiga Fibreglass Mat (normally utilized as “INNERWRAP”) and impregnated Twiga Fiberglass Mat (as “OUTERWRAP”)

Twiga Pipe Wrap conforms to International standards (AWWA C 203 latest versions / IS 10221 – 1982) for anti-corrosion coatings of pipe works as well as to the technical specifications provided by the major pipeline engineering groups.

- High tensile strength / breaking, tear strength – Resistant to longitudinal / transverse tension, provides reinforcement, protection from mechanical damage due to strain on pipe during handling – laying, commissioning & operation, withstand pressure due to soil movement, cold bending etc.

- Chemical Resistant (Inert) – Chemically stable, compatible with anticorrosive chemicals / coal tar and bitumen, resist degradation from corrosion electrolyte, unaffected by weather agents, withstand attack from bacteria, chemicals contained in soil, no mould growth

- High temperature resistance / tolerance – thermally stable, stable up to 288 0C, can be used in both hot & cold application, unaffected under load in hot bitumen at 288 0C, structural, composition stability

Features & Benefits:

- Flexible – Pliable, do not crack (yarn tear) & U.V.Protection

- Can be easily impregnated, uniform coating

- Inorganic composition – non biodegradable, does not rot and decay.

- Hydrophobic – does not absorb moisture, when applied with coal tar, it is impermeable to water

- Fire properties – Non inflammable (phenolic resin), reduce fire hazards

- High tensile strength, Chemical Resistant & Smooth surface

- Additional strength added by yarn reinforcement spacing option.

Waterproofing & Damproofing treatment with glass fiber tissue based felts

The characteristics of Twiga Fiberglass Tissue conforms to the various requirements of the sector and the membranes manufactured with the reinforcement material are suitable for all types of waterproofing systems, Twiga Glass Fibre Tissue conforms to the standards for reinforcement of felts and bituminous membranes for waterproofing systems.

As a base membrane in Coal Tar Pitch and Bitumen Felts, Twiga fibreglass tissue used is flexible uniformly bonded, mat composed of chemically resistant borosillicate staple glass fibres, distributed in a random open porous structure, bonded together with a thermosetting resin.

As aVapour Barrier for Thermal Insulation System Protection

When pipes and vessels are operating at lower than ambient temperatures, they are normally insulated for maximum plant efficiency. Moisture vapour may migrate through the insulation or its joints, condense at the dew point temperature, and freeze if the temperature reaches OO C.

Wet insulation can be up to 20 times less efficient than dry insulation, whilst freezing can cause physical break-up of the insulation structure because water expands on becoming ice. Hence requirement of Vapour Barrier becomes critical and Twiga Fiberglass Tissue improves handle ability and provides support to Insulation material.