ROOF & HVAC INSULATION

The main focus of this division is to provide a range of insulation products and solutions to the Heating, Air conditioning Industry and Roof Insulation Industry. The short description given below will explain the product we import and its applications and which markets are serviced through this division.

ROOF & HVAC - Products Range

Aluminum Foil

SISILASION Heat Reflective Roofing is of superior quality and comes highly recommended by Consultant Architects and leading Contractors. It is a multi-laminated Aluminium foil manufactured in Australia, using the best of raw materials. It is ideally used under the roof, in walls, behind cladding or under timber floors for residential and commercial buildings. Can combining with Glasswool/ Rockwool/ Mineralwool/ Foam Insulation.

Aluminum Tape and BRC Welded Roofing Mesh

Aluminum Tapes are available in two types as Reinforced and Non-Reinforced with different sizes starting from 2” up to 6”. This product we use to join the insulation.

BRC Welded Roofing mesh we use in fixing of Reinforcement solutions to the construction industry. This reinforcing mesh has a wide variety of uses ranging from the ordinary house to heavy industry.

Insulation Pins

.

Perforated Base Insulation Pin with a Self-Locking Washer are used to support either batt insulation or rigid board insulation on walls, ceilings or roof applications. The insulation pin has a 25mm x 25mm perforated base comes in 38mm and 65mm lengths. Self-locking washer is placed at the end of the nail to insure that the batt or board stays in place. When using adhesive to secure the anchors, the adhesive should be maintained at room temperature. The spindle pin installation should be completed and the glue should be given about 24 hours before the batts or boards are impaled.

Everything for the Fiberglass Industry

GELCOAT | RESIN C.S MAT | WOVEN ROVING | SURFACING TISSUE

CONTINUOUS ROVING | CATALYST M.E.K.P | MOULD RELEASE WAX

ARMAFORM PET | FOAM CORE | TALC POWDER | ACETONE | ACCELERATOR | PIGMENTS

Polyester Resin – SHCP 2719L-CM

GENERAL DESCRIPTION

SHCP 2719L-CM is a quick curing unsaturated polyester resin for making decorative panels and rooting sheets. It is waxed and pre-accelerated .

SIICP 27I9L-CM is clear and transparent. It possess low shrinkage and is ideal for making a variety of casting corrugated plain or translucent sheets for uses in roofing. The applications arc for green houses, poultry houses, swimming pools patios, porches, gymnasiums, car ports, corridors, roofing and skylighting for factories and warehouses.

The use of 2719L-CM/ UV is highly recommended due to it’s good weathering and ultra violet resistance.

SPECIFICATIONS

Liquid SHCP 27 I 9L-CM polyester resin has the following characteristics:

- Appearance : Clear

- Viscosity at 30℃ : 3 – 5 poise

- Gel Time at 30℃ : 4 – 7 rains

- Cure Time at 30℃ : I 5 – 25 mins

- Peak Exothermic Temperature : 110 – 120℃

- Stability in the Dark below 25℃ : 6 months

USAGE

SHCP 27I9L-CM performs best when it is completely cured. To do so, a proper combination of catalyst and accelerator must be used at room temperature for a sufficient period of time. Generally, 1 percent of catalyst (BUTONOX M-50 MEKP) is used.

Adjustments for shorter or longer geltirne can be achieved by ranging the quantities of catalyst and/or accelerator used. As a rule, however, the amount of catalyst used should not be more than 2% or less than 0.5% while that of accelerator should range between 0.4% and 1%. Be sure to measure accurately. When used with filler, depend on the percentage of tiller being added the amount of catalyst will need to be adjusted accordingly for the desired geltime.

Ensure that the accelerator must be completely mixed into the resin before catalyst is added in order to avoid a direct blending which due to a violent reaction may result in an EXPLOSION.

Since the viscosity increased as the storage period of resin lengthens, Styrene Monomer can be added to lower it to a desired level. However owing to difficulties in presenting information applicable to all situations, no warranty is expressed or implied and users are recommended to carry out their own tests to determine the applicability’ of the above information and the suitability of SHCP resin for their particular requirements.

STORAGE

SHCP polyester resin will remain stable if stored in the dark and at temperatures below 25℃. Their stability however deteriorates markedly at higher temperatures, especially when they are directly exposed to sunlight. Hence they should be kept in a cool, dark place.

PACKING

SHCP polyester resin is packed in steel drums of standard size, containing in net weight.

Polyester Resin – SHCP 2668 CM-M

APPLICATIONS

SHCP 2668 CM-M is a special formulated resin exclusively design for sheet lamination application. Such as roofing sheets, green house and etc….

SHCP 2668 CM-M is non-thixotropic, clear appearance and promoted. SIICP 2668 CM-M exhibits good impregnated with tihredass to show an excellent effect of transparency on the products.

SPECIFICATIONS

Liquid SHCP 2668 CM-M polyester resin has the following characteristics:

- Appearance – Clear

- Viscosity at 30℃ – 6 – 8ps (Brookfield LVT viscometer, #2, 30rpm)

- Accelerator (6% Cobalt) – 0.5%

- Gel Time at 30℃ – 8 – 12 minutes

- Cure Time at 30℃ – 20 – 40 minutes

- Peak Exothermic Temperature – 130 – 140℃

These are laboratory conditions at the end of batch production using 1% catalyst (Butanox M-50 MEKPO).

USAGE

SHCP roofing sheet resin performs best when it is completely cured. To do so, a proper combination of catalyst and accelerator must be used at room temperature for a sufficient period of time. Generally, I percent of catalyst (BUTANOX M-50 MEKP) together with 0.5 percent of accelerator (6% cobalt content) is used for 2668 CM-M.

STORAGE

SHCP unsaturated polyester resin will remain stable for about 6 months from date of factory manufacturing provided resin is stored in the dark and not exposed to moisture and the recommended storage temperature should not exceed 25℃ and the containers should not be opened until they are required for use. Their stability however deteriorates markedly at higher temperature especially when they are directly exposed to sunlight. It is advisable to finish it within three months.

However, owing to difficulties in presenting information applicable to all situations no warranty is expressed or implied and users arc recommended to carry out their own test to determine the applicability of the above information and the suitability of SHCP resins for their particular requirements.

Polyester Colour Paste

THE FRP STANDARDS COLOUR RANGE is made up of 36 popular shades. The colours are blends of high quality inorganic and organic pigments finely dispersed into a monomer free unsaturated polyester resin for maximum storage stability. They are to be used at between 8% and 12% in clear polyester gloat and at between 3% and 5% in clear polyester baking resign filled or fire retardant system may affect the shade.

FURTHER GUIDANCE mixing with the parent resin is best done with a low speed mechanical stirrer or by a suitable hand held tool. High speed mixing may result in are voids in the final article. All the colours are manufactured under ISO 9002 quality system to a tolerance of CILELAB D.E. 0.5 from master standard. However, for technical reasons associated with colour printing the above colour swatches may not be truly representative of the final colour achieved. Uniformity of the colour can be affected by:

- Batch variation of the clear resin or gelcost particularity with paler shades

- Incorrect weighing of the color paste. The addition must be done by weight due to variation in specific gravities of the colour paste. Varying gelcoat thickness.

- Inaccurately added catalyst and accelerators.

Woven Roving

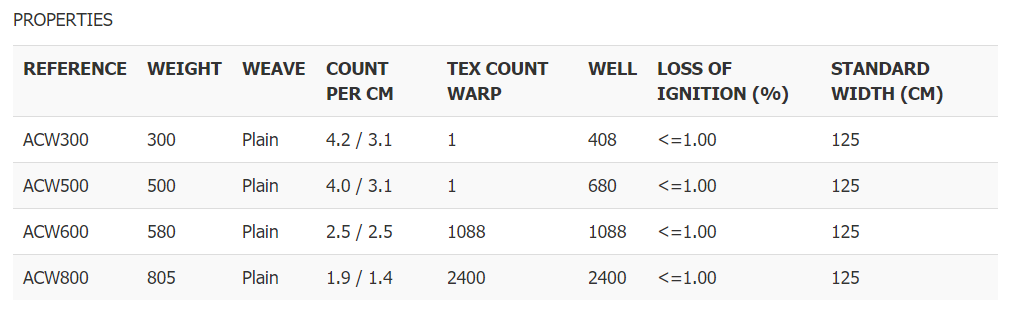

ROPERTIES

- Excellent conformability

- Fast wet out

- High mechanical properties

Woven reinforcements arc made from E-glass direct roving. The fibers arc coated with a slime coupling agent that makes woven roving cloths compatible with most common polyester, vinyl ester and epoxy resins.

Our standard series are bi-directional, plain weave cloths, in 100 cm or 125 cm in width. Upon request, other weights and widths arc available under specific conditions in relation with feasibility and minimum quantities.