Cooling Towers

S.L.J selected innovative branded cooling towers are of the highest industry quality standards certification along with its dependable long life performance backed by our very own SLJ Installation, Service, Maintenance and After Sales division.

Cooling towers are heat rejection devices used to transfer process waste heat to the atmosphere. Two key elements are Water & Air.

Committed to freezing climate change by improving cooling through the limited use of natural resources.

Open Cooling Towers

Open cooling towers discharge heat from water-cooled systems into the atmosphere. The hot process water is distributed over a fill pack (heat transfer media) to interface with air blown by a fan through the cooling tower. During this evaporative cooling, a small part of the water evaporates while cooling the remaining process water.

The key benefits of open cooling towers are:

- optimal cooling, as proved by lab tests

- allowing low process temperatures

- open cooling towers have a small footprint

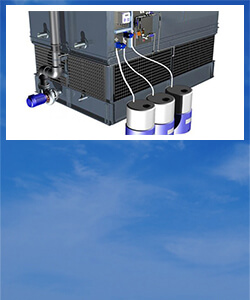

Closed Circuit Cooling Towers

Closed circuit cooling towers or fluid coolers operate just like the open type, but dissipate the process fluid heat load into the ambient air via a heat exchange coil. This isolates the process fluid from the outside air, keeping it clean and free of contamination in a closed loop and creating 2 separate fluid circuits:

- An external circuit, in which spray water circulates over the coil and mixes with the outside air.

- An internal circuit, in which the process fluid circulates inside the coil.

During the evaporative cooling operation, heat goes from the internal circuit, via the coil to the spray water, and then to the open air as a portion of the evaporating water.

Refrigerant condensers

Evaporative condensers discharge refrigerant and air-conditioning heat, and consume minimal energy and water. They combine a cooling tower and a refrigerant condenser in a single unit and offer the following

Key benefits:

- Initial cost savings: cooling tower, condenser surface, water pump and piping in a single equipment unit

- Low system operating costs: low condensing temperatures for a more compact compressor using less power

- Low refrigerant charge, costs and environmental impact minimized

- Space-saving: up to 50 % area savings compared to comparable air-cooled installations.

These units evaporate a fraction of the water, eliminating refrigerant heat and condensing within the coil.

Adiabatic cooling

Adiabatic products are air-cooled coolers or condensers with adiabatic pre-coolers. Before the fan draws the ambient air through the finned coil, the air is pre-cooled adiabatically when traversing an humidification pad. This evaporates the water in the air, thus boosting the cooling capacity.

Key benefits

- low process temperatures

- saves more than 80% on annual water compared to cooling towers

- up to 40% increased capacity compared to dry cooling (air temperatures approaching wet bulb temperature)

- reduced energy consumption

- operational safety: no water recirculation, no stagnant water, no aerosol generation, no water carry-over.

Ice Thermal Storage

As the name suggests, they use ice to build and store cooling when cooling demand and/or energy rates are low (mostly overnight), which the system then uses for air-conditioning or process purposes when energy rates are high (mostly daytime).

Benefits

- Refrigeration systems up to 50% more compact.

- Operational cost savings: ice formed overnight with cheaper electricity.

- Lower energy consumption basing the cooling system on average conditions rather than peak reduces power requirements and the refrigerant charge.

- Reduced carbon footprint: Most of the cooling occurs overnight when condensing temperatures are lower and the cooling system requires less energy.

- Less compressor maintenance since the compressor operates continuously at full capacity and not under fluctuating partial load.

- Thermal storage systems provide back-up cooling.

Water Treatment & Filtration

Evaporative cooling equipment needs good water care and filtration systems to protect components and heat exchange surfaces and control corrosion, scaling and fouling. It is also vital in avoiding the proliferation of harmful bacteria, including legionella, in the recirculating water.

Automatic bleed control

An automatic bleed system in an evaporative cooling system controls the dissolved solids in the recirculating water. Conductivity based, automatic bleed-off of the recirculating water using a motorised bleed is the most reliable and accurate control method avalaible.

Water treatment chemical dosage

BCP dosing and control technology: an accurate water care program with state-of-the-art electronic control.

The BCP packages are compatible with any chemical water treatment supplies. BAC offers 2 typical package solutions:

Mechanical filtration systems

- Side stream filtration: separator and media filters that efficiently remove suspended solids to reduce system cleaning and optimize water treatment.

- Sump sweeper piping: a water agitation system that prevents accumulation of sediment in the cold water basin and reduces system cleaning costs. This also boosts the service life by eliminating the source of underdeposit corrosion.

Package & Industrial Cooling Towers

Offers various types of cooling tower ranging from bottle type and square type induced draft counter flow cooling tower, square type induced draft cross flow cooling tower with robust and anti-corrosive FRP material, counter flow and cross flow type field erected cooling tower with quality treated wood structure and pultruded FRP structure cooling tower, closed circuit cooling tower, plume abated cooling tower, CTI (Cooling Technology Institute) certified TLC series cross flow cooling tower, and to a newly innovated and patented Fan less cooling tower that incorporates no mechanical moving parts and provides super low noise operation with no vibration, therefore it is ideally for environmental concern location such as hospital and hotel.

Other than cooling towers,we also provide FRP tank, Chemical Storage tank, and other customized FRP products.